Exothermic Welding System

|

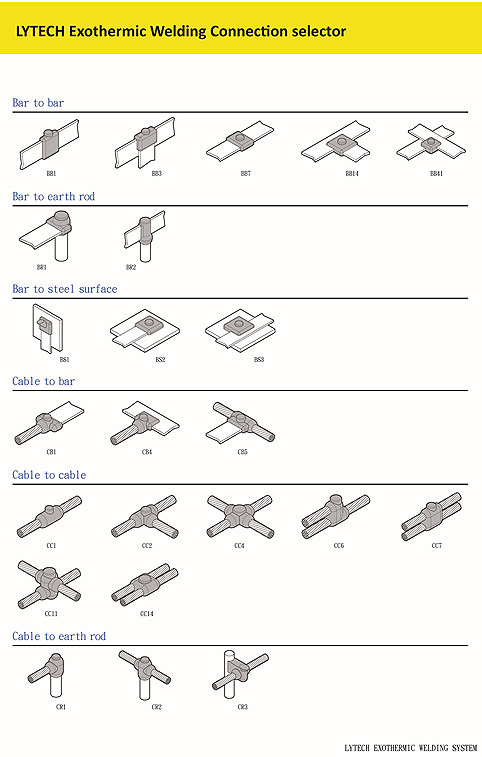

LYTECH offer a complete and comprehensive exothermic welding which is a cost efficient way of making large or small numbers of high quality electrical connections. LYTECH offer a simple, self -contained system that uses the high temperature reaction of aluminum and copper oxide which work with a graphite mold to form a permanent and robust electrical connections. |

Exothermic Welding System is commonly used in:

|

Advantages of LYTECH Exothermic Welding System

|

Most LYTECH exothermic welding connection is at least twice the cross-sectional area of the conductors being joined and has an equivalent or higher current carrying capacity. With more than 90% copper content of the alloy, it offers excellent corrosion resistance properties.

LYTECH Exothermic Welding System is:

|

|